Civil Engineering :: Steel Structure Design

-

The tensile strength of mild steel for bolts and nuts should not be less than

-

A riveted joint may experience

-

With a percentage increase of carbon in steel, decreases its

-

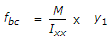

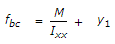

In a built up beam actual bending compressive stress fbc is given by (when y1 is the distance of the edge of the beam from the neutral axis).

-

In double lacing, the thickness t of flat lacing is

-

When the length of a tension member is too long

-

An imaginary line along which rivets are placed, is known as

-

The allowable stress in axial tension is generally kept less if thickness of the member is more than

-

The maximum permissible slenderness ratio of compression member carrying dead and superimposed load, is

-

The safe working pressure for a spherical vessel 1.5 m diameter and having 1.5 cm thick wall not to exceed tensile stress 50kg/cm2 , is

Whatsapp

Whatsapp

Facebook

Facebook